Inventory

With inventory policy statements we can take all the guesswork out of how many parts we need to keep on hand, and when we need to re-order to keep up with current sales levels.

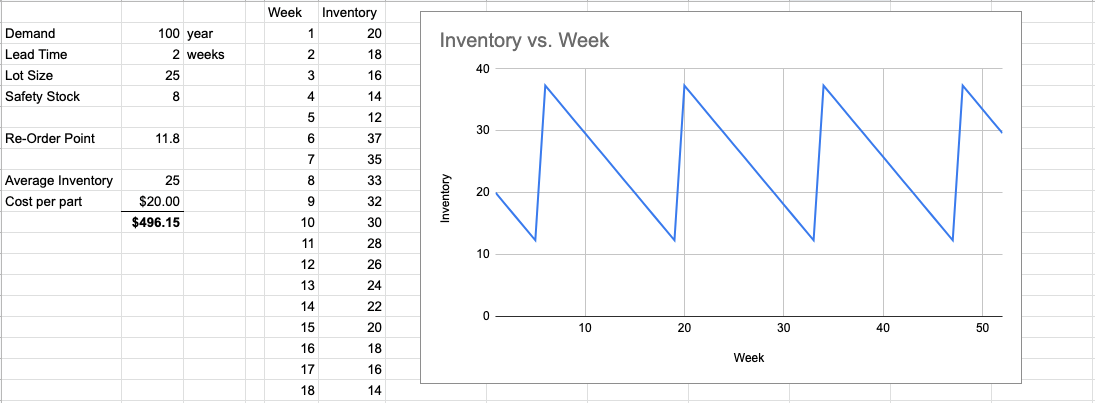

Inventory follows a sawtooth...

Our goal is to arrive at this statement for each part, sub-assembly, or product:

When inventory is at Re-Order Point order Lot Size

Use this generator to create nice-looking inventory labels without needing to do any math or design!

Then print at 100% scale and cut out this 4"x6" label.

- Place it near the inventory stack.

- Make it easy to see!

When inventory is at Re-Order Point order Lot Size

Inputs

Demand: per

Lead time:

Lot size:

Safety stock:

Printed on

Created by

Additional details:

Inventory Equation - When to order?

Re-Order Point = Demand x Lead Time + Safety Stock

Re-Order Point = per week demand x weeks lead time + safety stock

Inventory Period = Lot Size / Demand

Lot size of Q / D per week demand = inventory period of T weeks

Notes:

- keep the inventory period as low as possible

- managing inventory is a tricky balance between holding enough stock to fulfill orders, and not tying up cash

- as a small business, err on the side of not tying up cash!

- adjust as necessary - things change as the business evolves and getting stuck with unsellable inventory is as bad as it gets...

- if printing a screenshotted label, scale to 75% to keep same size as others